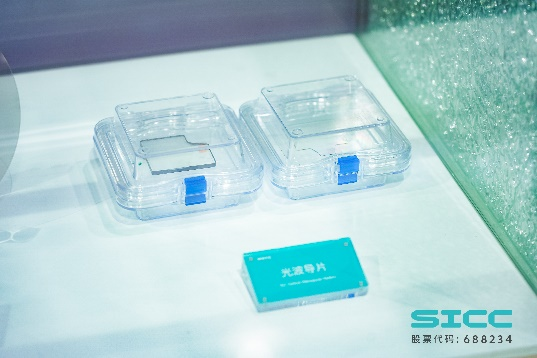

Shanghai, March 2025 — At Semicon China 2025, one of the world’s premier semiconductor expos, SICC made a powerful statement by unveiling its full portfolio of 300mm silicon carbide (SiC) substrates — including high-purity semi-insulating, conductive P-type, and N-type variants. Among them, the 300mm SiC optical waveguide wafer drew exceptional attention, positioning SICC at the forefront of innovation for next-generation AR and virtual display technologies.

Technology Breakthrough: The 300mm Leap

Following its landmark debut of the world's first 300mm conductive substrates at Semicon Europe 2024, SICC’s latest showcase of all 300mm products represents another milestone in the industry’s transition into the large-size wafer era. With a surface area 2.5 times greater than an 150mm wafer, the 300mm substrate significantly boosts chip yield while slashing unit costs — a game-changing evolution in the SiC sector.

The comprehensive 300mm product matrix is a testament to SICC’s mastery in crystal growth, defect control, precision processing, and inspection. Industry experts now widely anticipate 2025 to be the inaugural year of large-size SiC breakthroughs.

These technological advancements will not only accelerate the deployment of high-voltage applications — including new energy vehicles, photovoltaic systems, smart grids, and 5G base stations — but also pave the way for emerging markets such as AR wearables, satellite communication, and the low-altitude economy, driving the algorithmic infrastructure of the Internet of Everything.

Silicon Carbide: Revolutionizing AR Glasses

The AR industry is undergoing a paradigm shift. In 2024, Meta became a trailblazer by integrating silicon carbide-based optical waveguides into its AR glasses — marking the start of a new trajectory for optical performance and material innovation. According to Meta, producing 1 million pairs of AR glasses could require up to 300,000 150mm SiC wafers.

Traditional AR optics rely on high-refractive-index glass or resin, which face trade-offs between image quality, weight, and durability. While glass offers clarity, its density makes headsets heavy and uncomfortable for long-term use. Resin, though lighter, struggles with heat deformation and yellowing over time.

Silicon carbide solves these issues elegantly — offering lightweight strength, superior thermal conductivity, and long-term optical clarity. As a result, SiC is rapidly emerging as the material of choice for next-generation AR hardware.

Material Advantages: Why 300mm SiC Optical Wafers Stand Out

SICC’s advanced 300mm SiC optical waveguide wafers bring multiple, transformative benefits to AR system design:

Lightweight & Durable:

With a density only one-third that of glass, SiC is both lightweight and exceptionally strong. Its colorless, transparent form resists oxidation and deformation, ensuring both aesthetics and longevity.

Enhanced Visual Experience:

SiC’s high refractive index (2.6) enables broader fields of view in AR/VR systems without increasing lens size. It also supports the integration of RGB waveguides into a single optical path — streamlining design and improving image fidelity.

Superior Heat Dissipation:

Conducting heat 400 times more efficiently than glass, SiC acts as a natural heat sink — preventing distortion or performance degradation under extended use.

Industrial Scalability & Cost Reduction:

Thanks to SICC’s breakthroughs in mass production and large-diameter crystal growth, 300mm wafers are rapidly becoming industrially viable. The larger surface area reduces material waste and enhances lens yield, dramatically lowering unit costs. As AR lenses represent a major share of overall device cost, these advancements are expected to significantly accelerate commercialization.

Strategic Vision: Building the Future of Optical Technology

SICC has spent years building deep expertise in semi-insulating substrates, pioneering technologies from raw material purification to 300mm crystal growth. With the AR industry entering a phase of rapid growth, SICC’s early investment in 300mm SiC optical waveguides positions it as a important player in next-generation optical materials.

Its customized large-size SiC wafers empower AR manufacturers with higher-performance, lower-cost core components — ideal for immersive experiences in work, entertainment, navigation, and communication. The seamless integration of large transparent screens in lightweight glasses is bringing the vision of “anytime, anywhere” computing closer to reality.

As SiC material processes continue to mature, AR optical performance will see further enhancements — delivering lighter, clearer, and more energy-efficient smart glasses to consumers.

With its 300mm silicon carbide technology, SICC is not only redefining what’s possible in AR optics — it’s laying the foundation for a smarter, more connected world.

SICC: Empowering the Future of Intelligent Living.